Our products

Isomed: implantologists at the service of implantologists

Isomed develops its products starting from the experience accumulated over 20 years in the service of implantology.

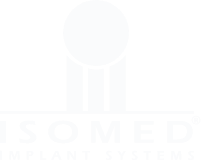

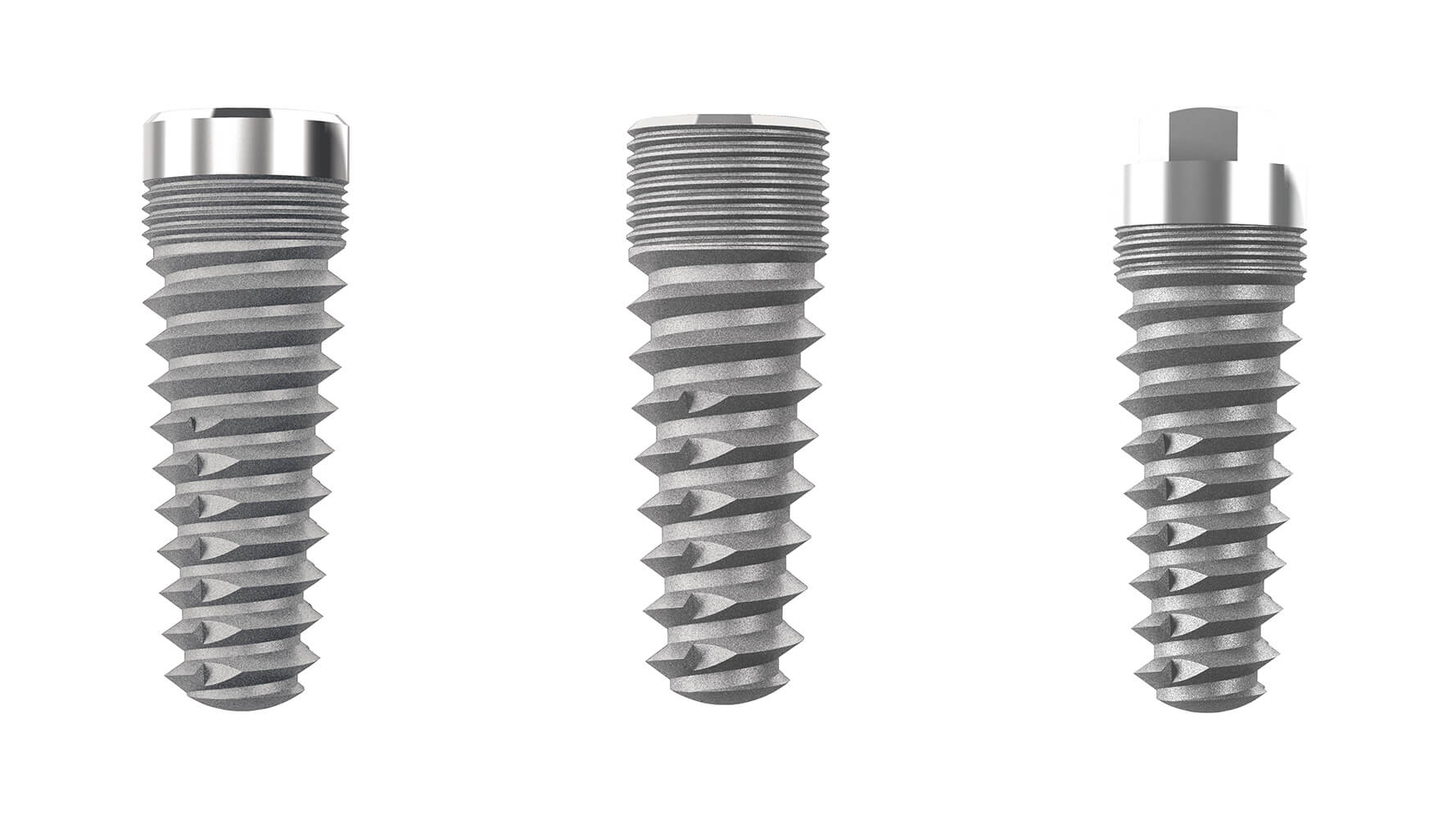

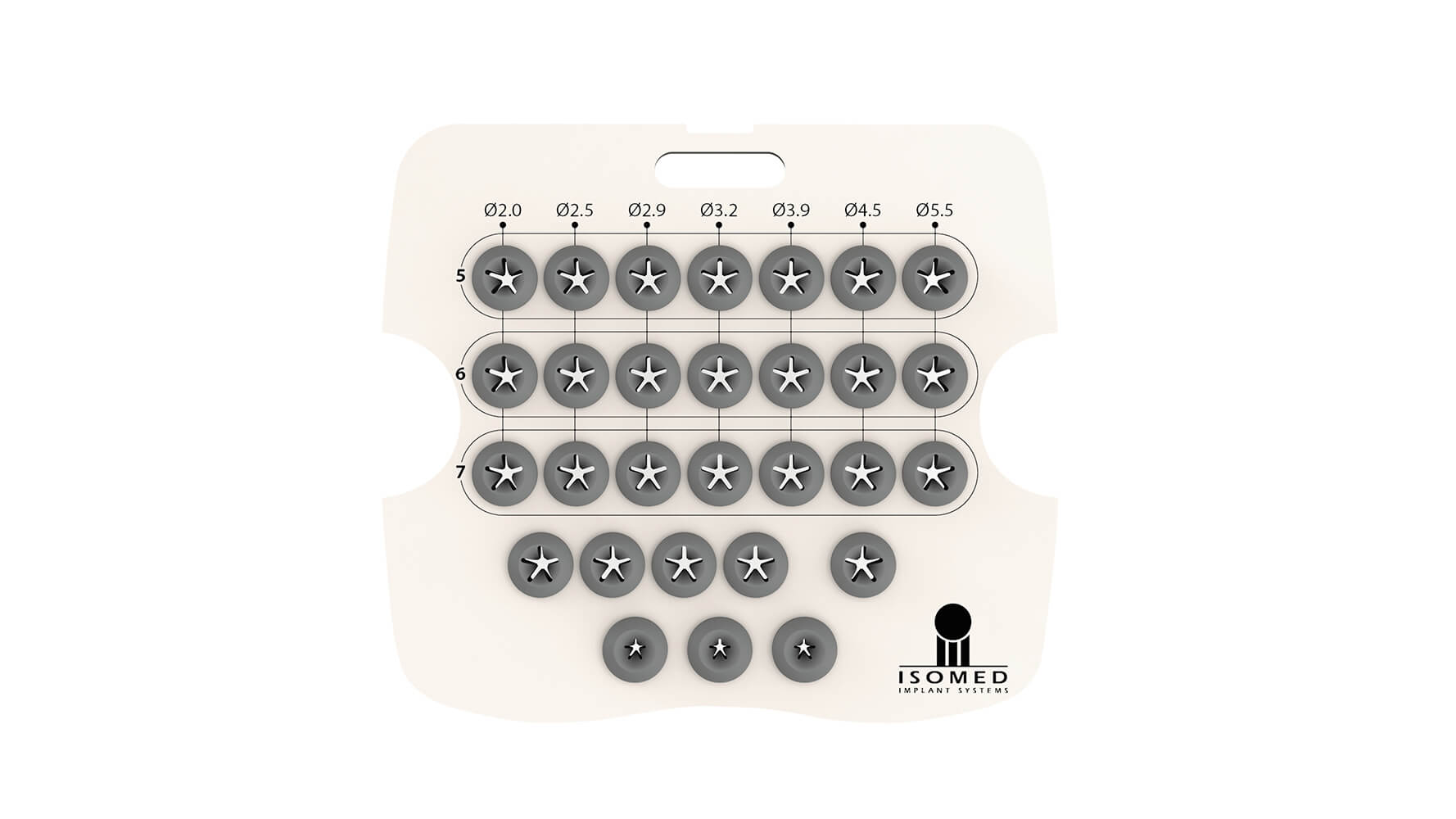

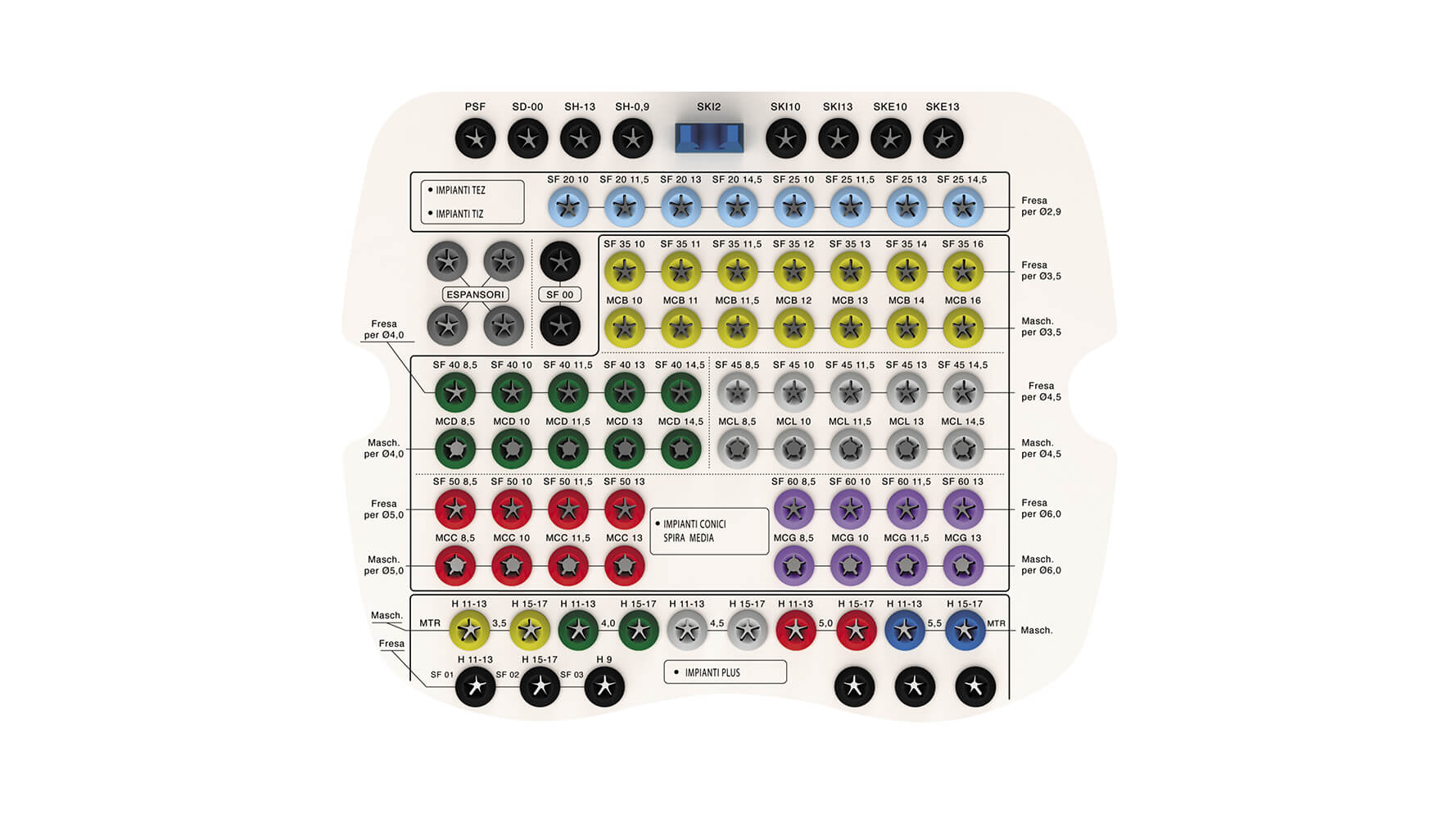

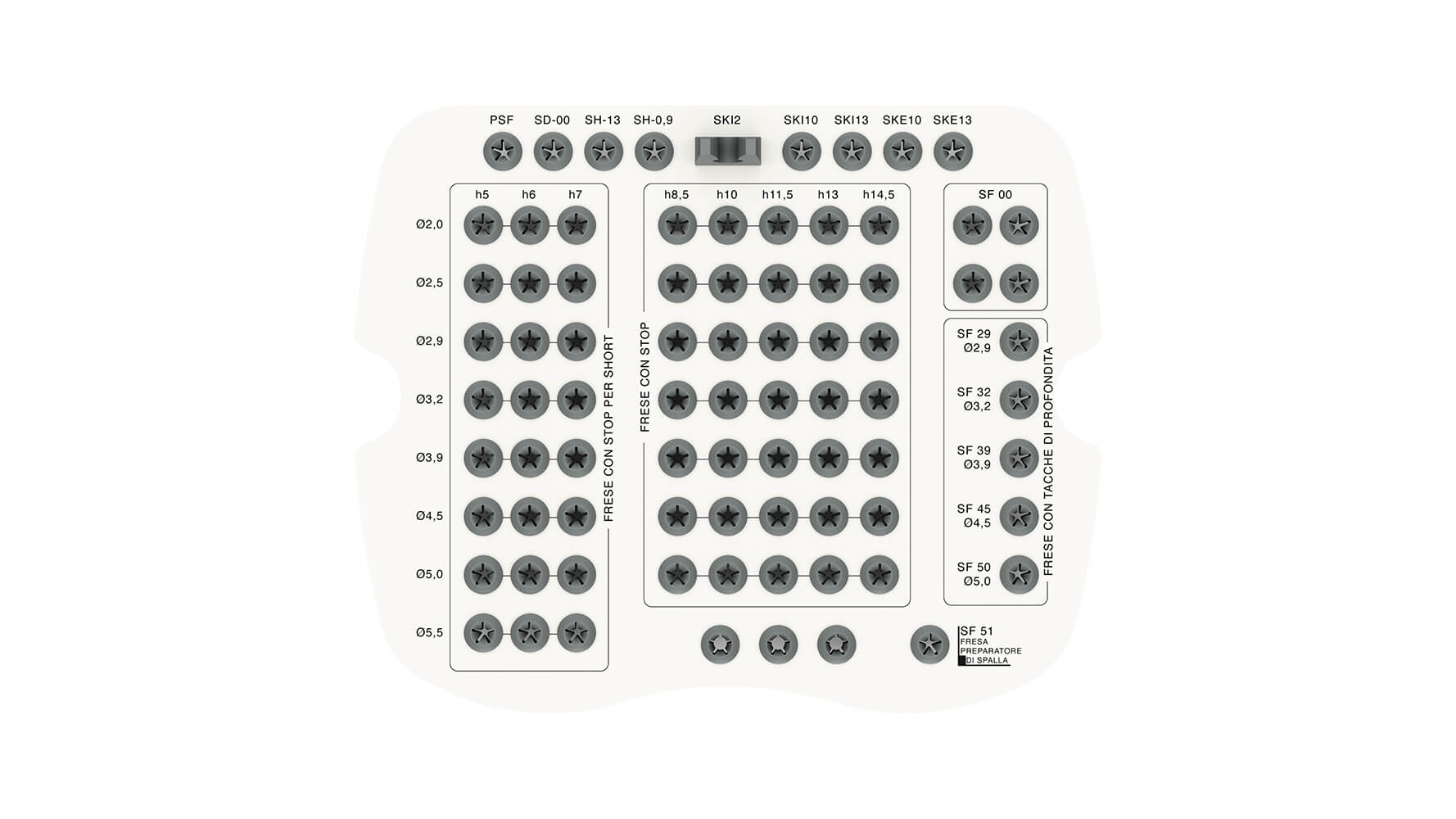

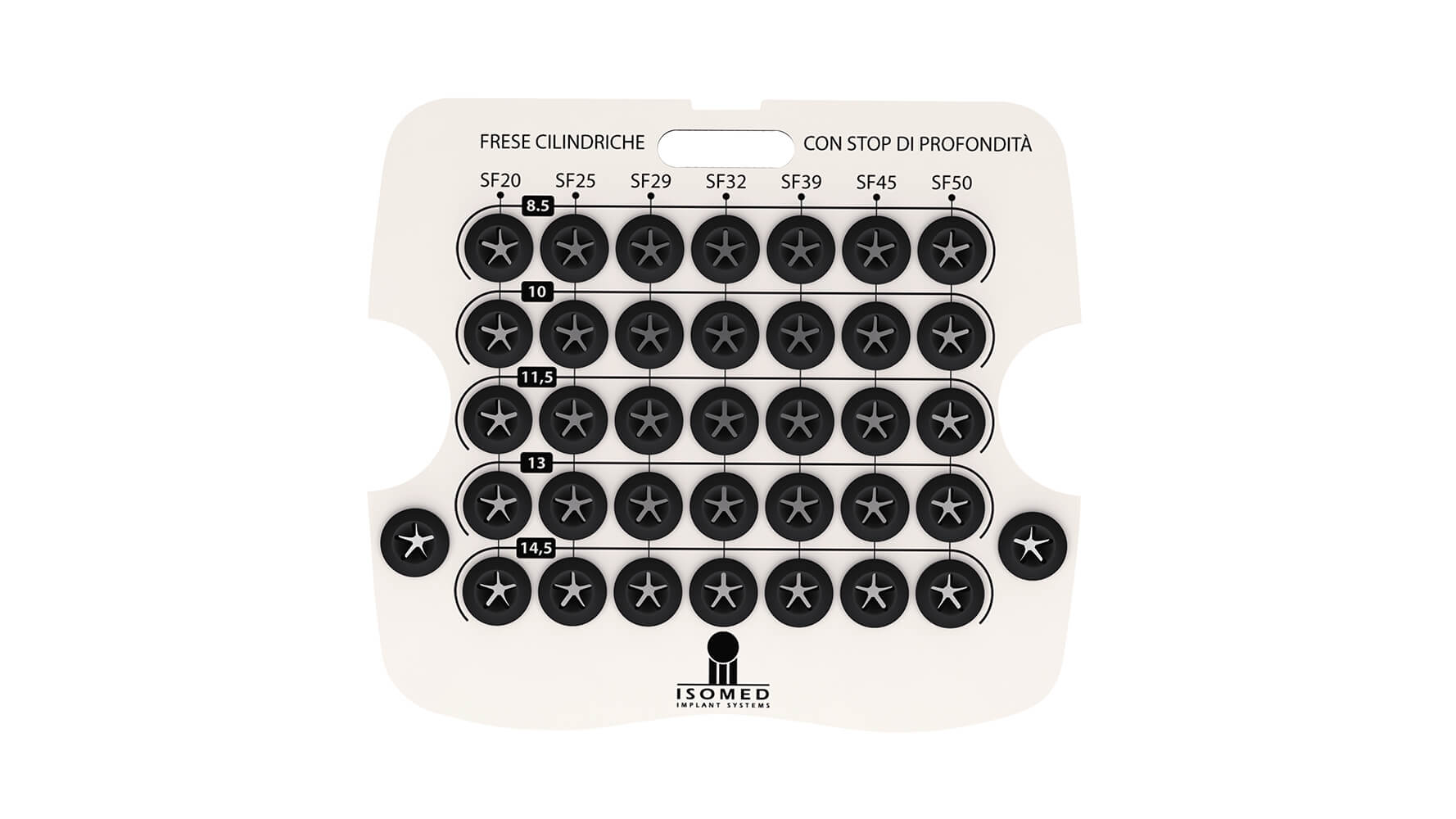

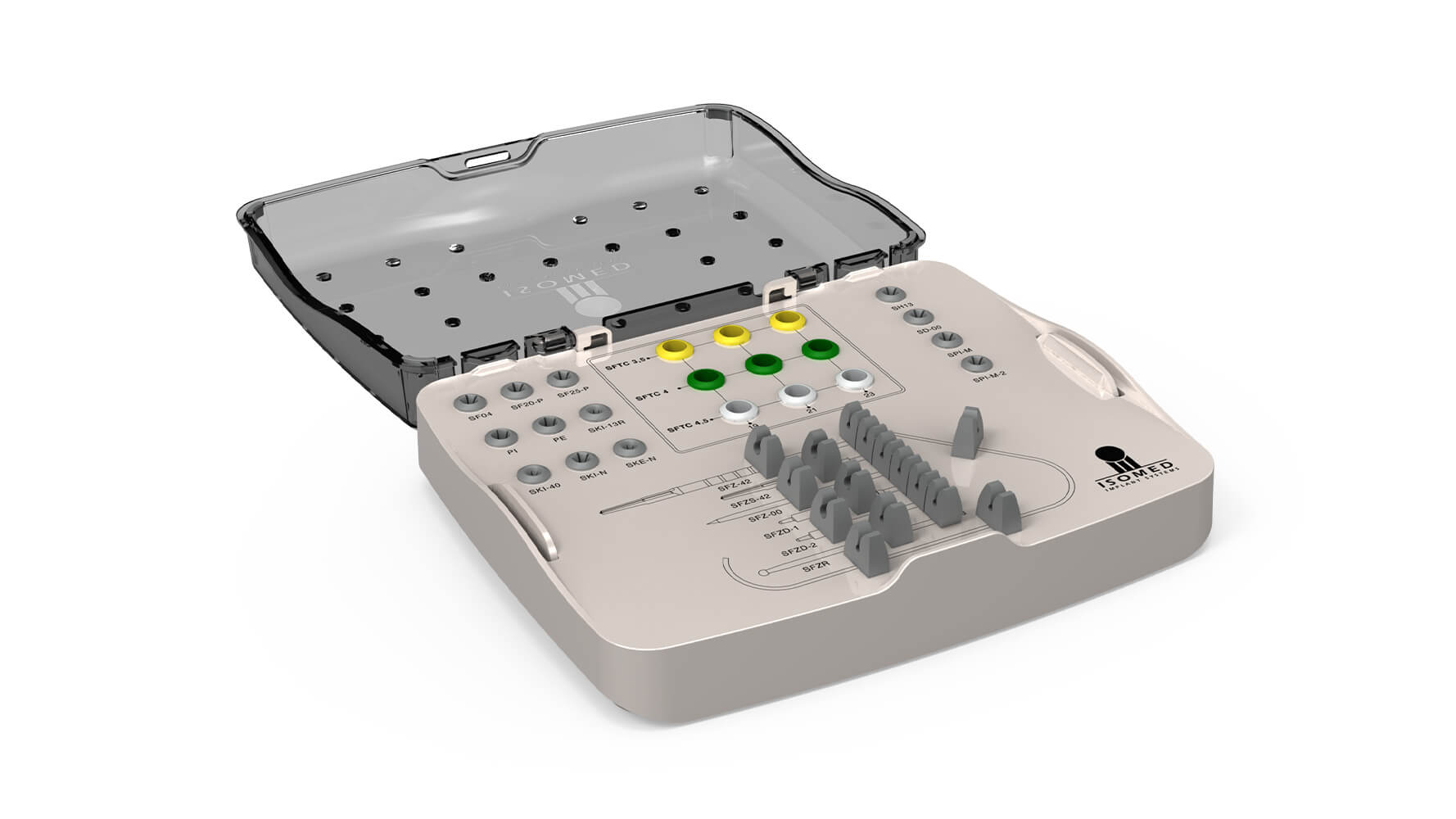

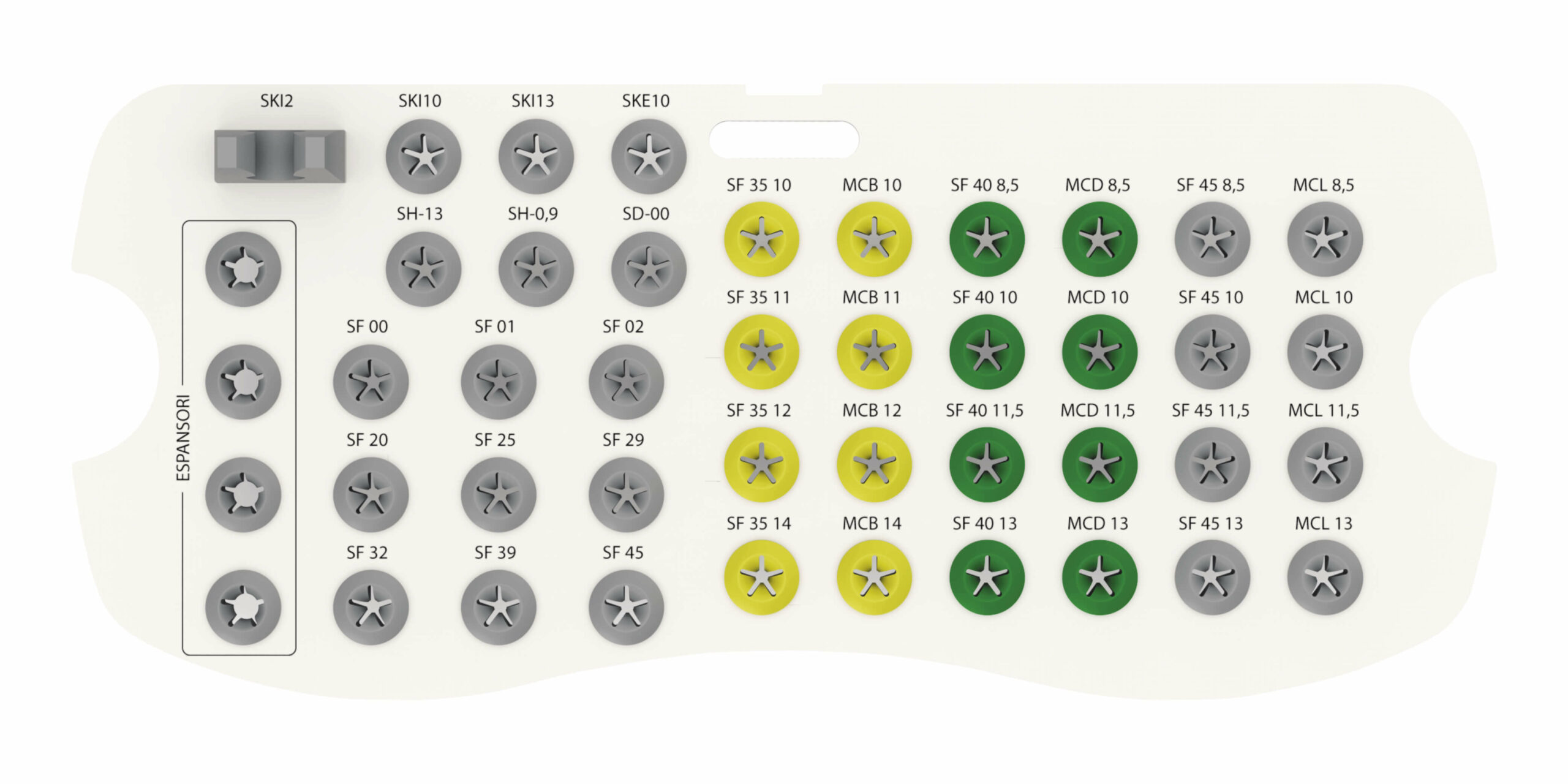

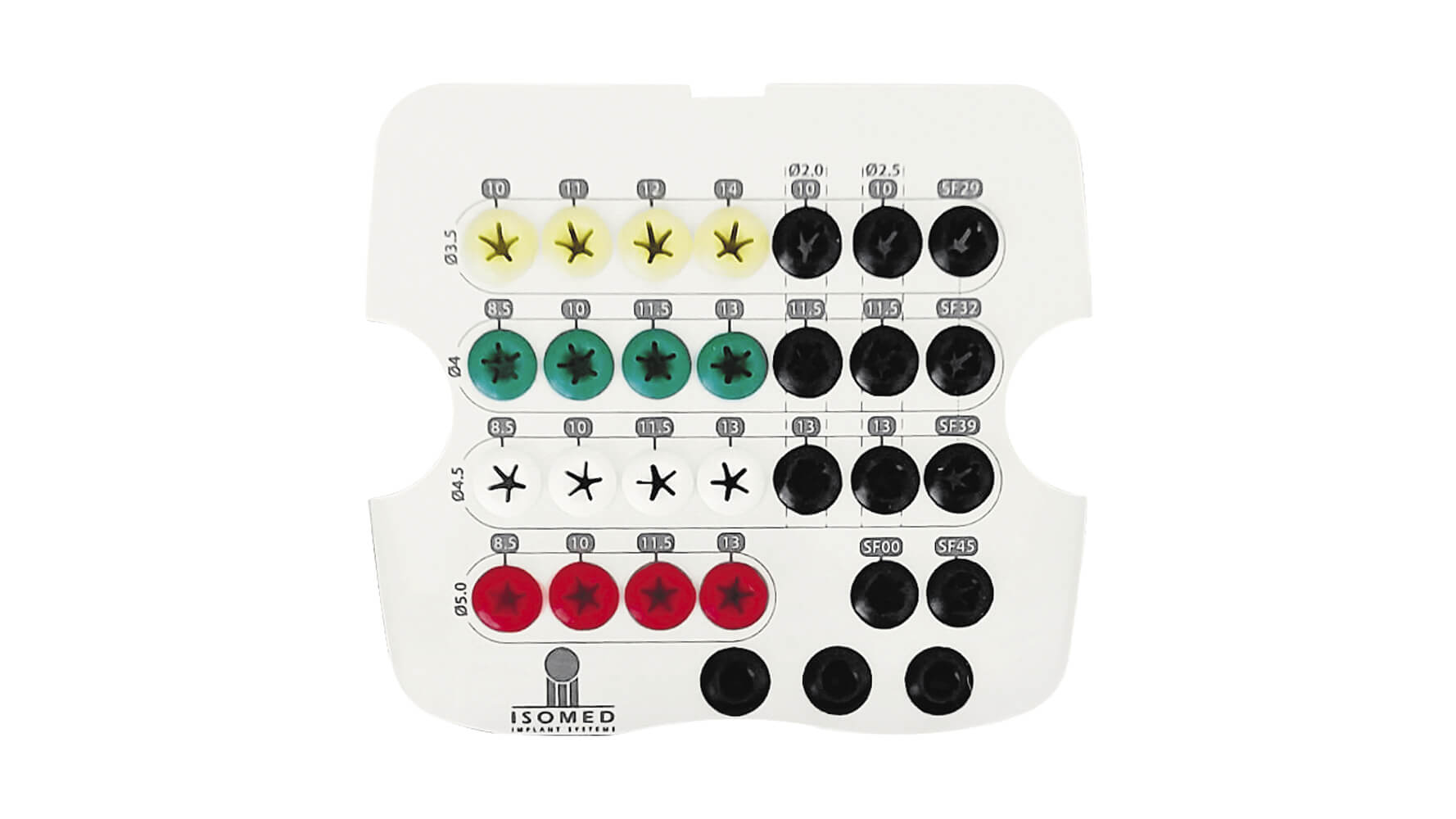

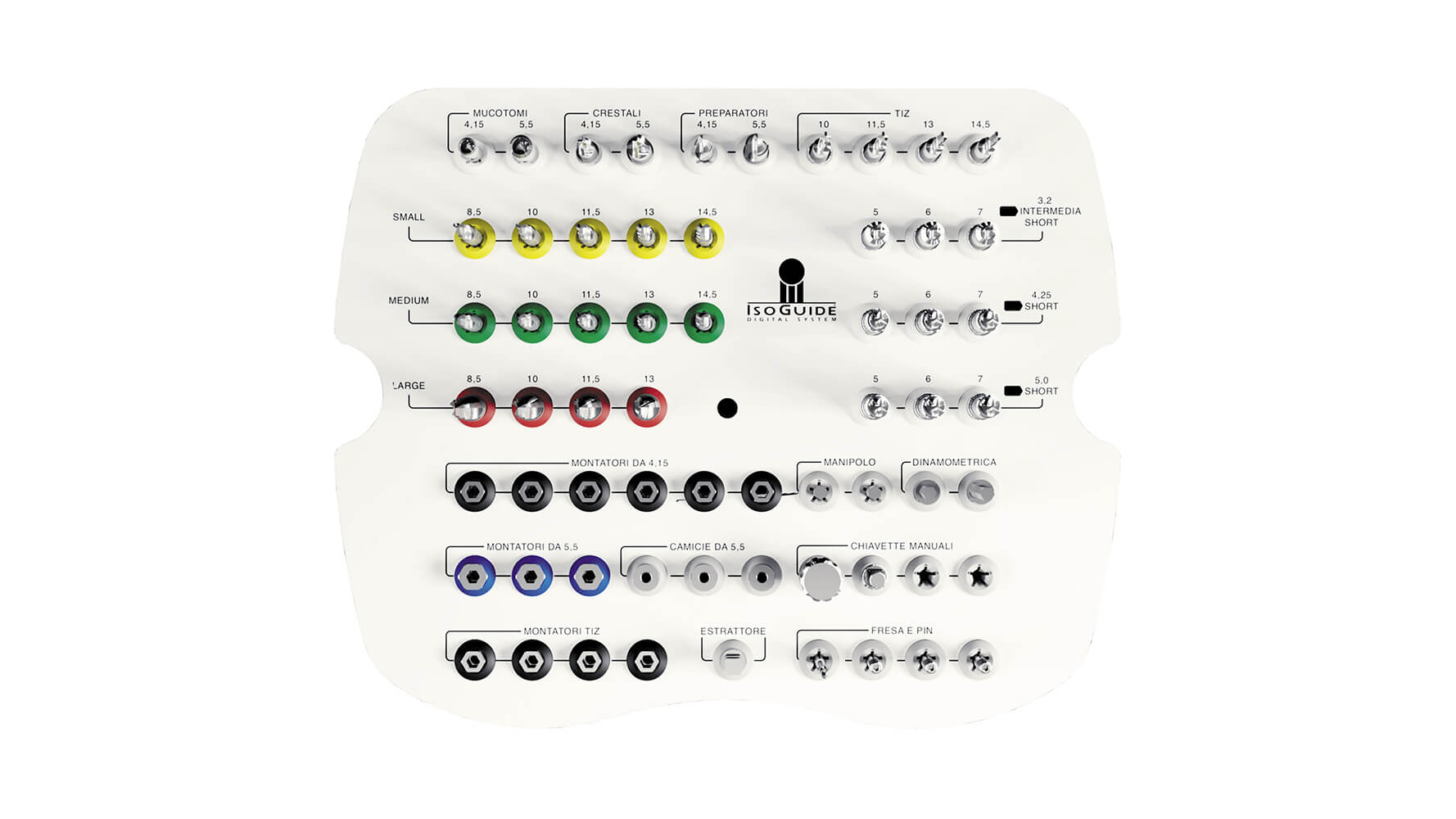

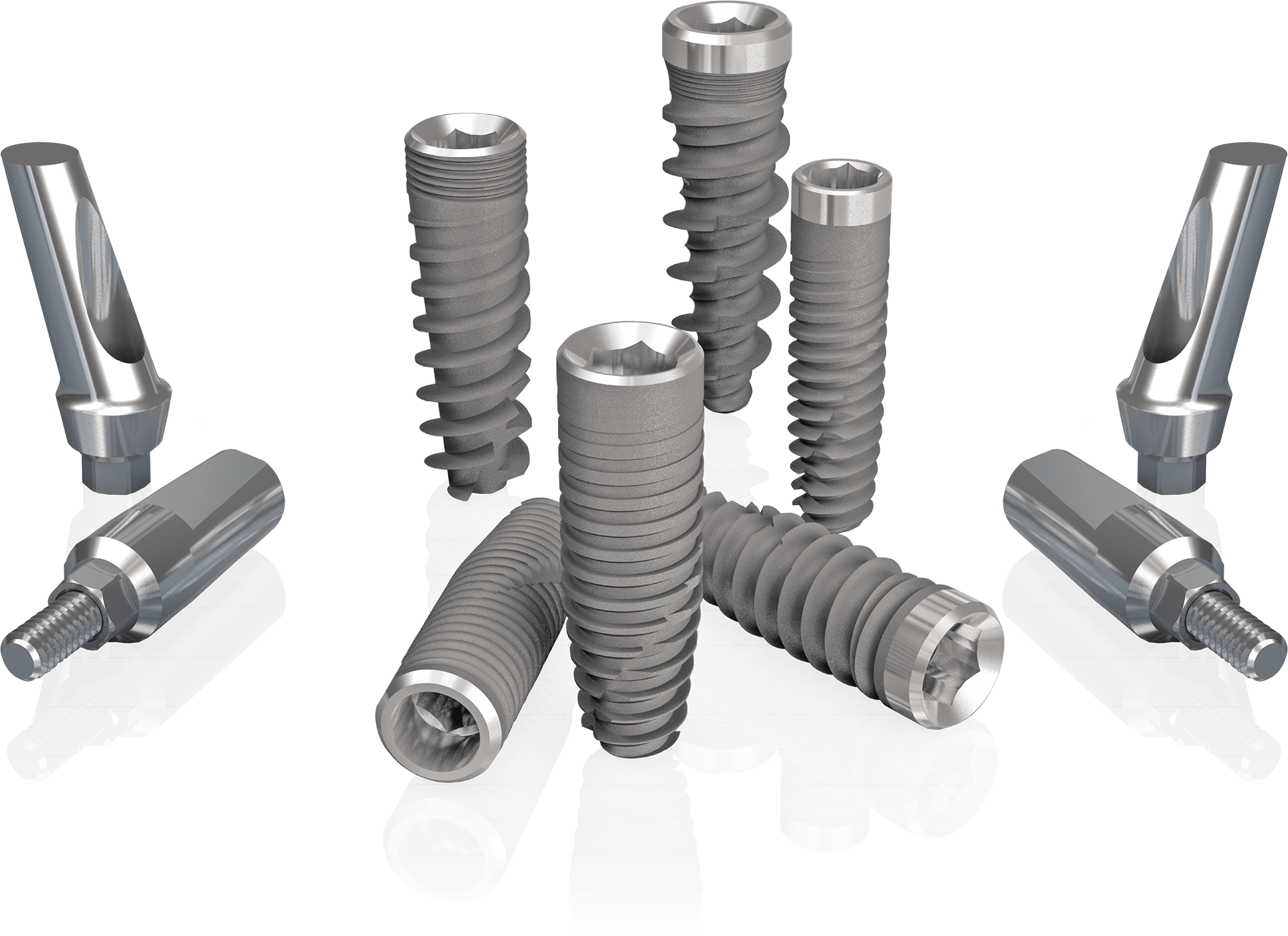

Our implant system are designed to provide a solution even in cases truly complex to manage, while our prosthetic components meet the criteria of precision and ease of use.

We offer to our partners digital and analogical solutions for the design of interventions in total safety and provide constant and qualified assistance.

A tool to ease your work

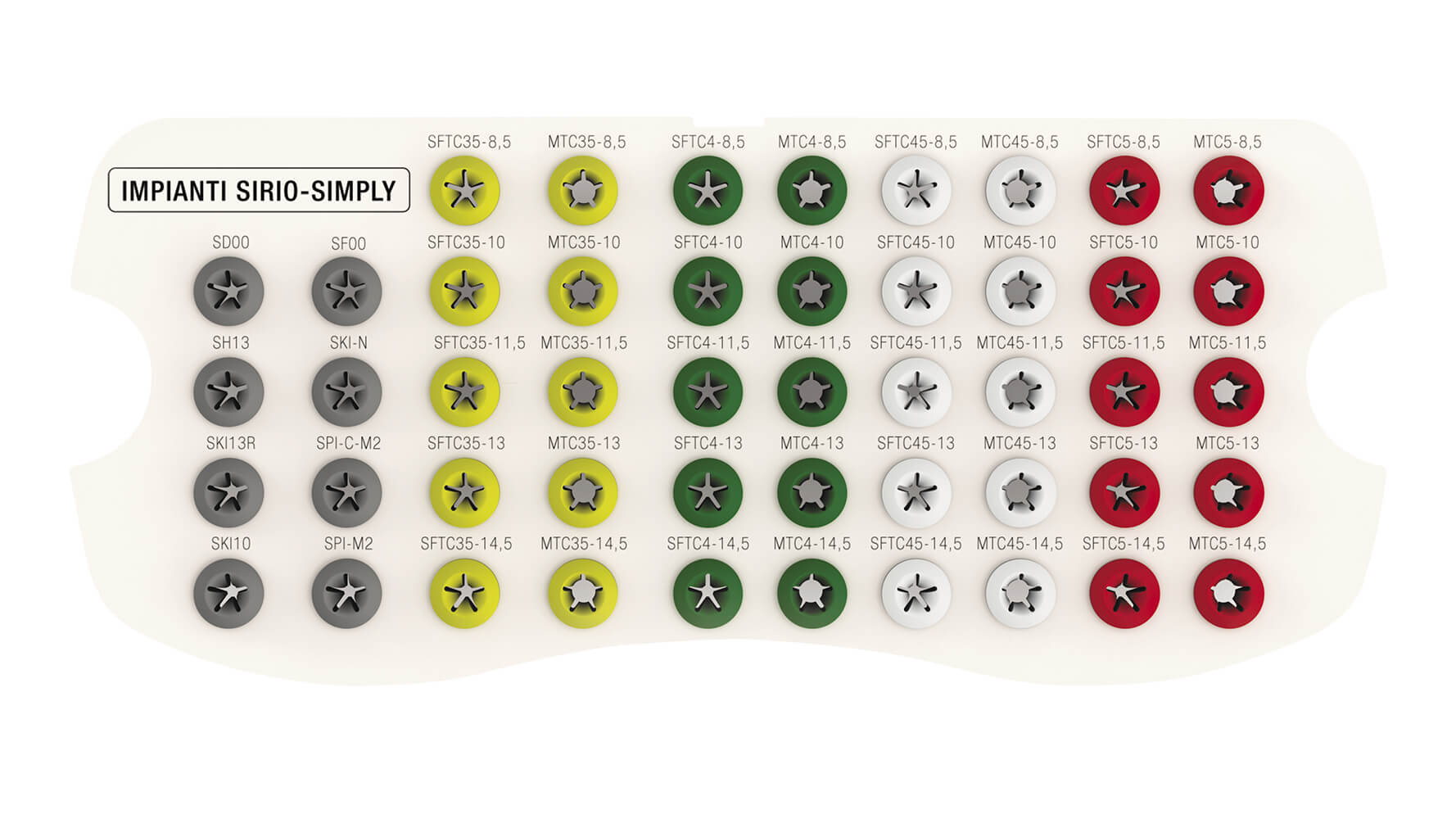

Each implant solution - we offer 23 of them - is designed to solve a specific problem of the patient, therefore of the clinician. We belive that our wide range of products provides a precise and thereofore simple solution, in any eventuality. Isomed has chosen to invest in complexity to allow implantologists to work simply.

Why should choose us?

Surgical assistance and advice to professionals at their practice or at the Isomed Clinical Center

Implantological consultancy (if necessary also remotely) and free evaluation of the radiological images

Modularity and compatibility with other implant systems

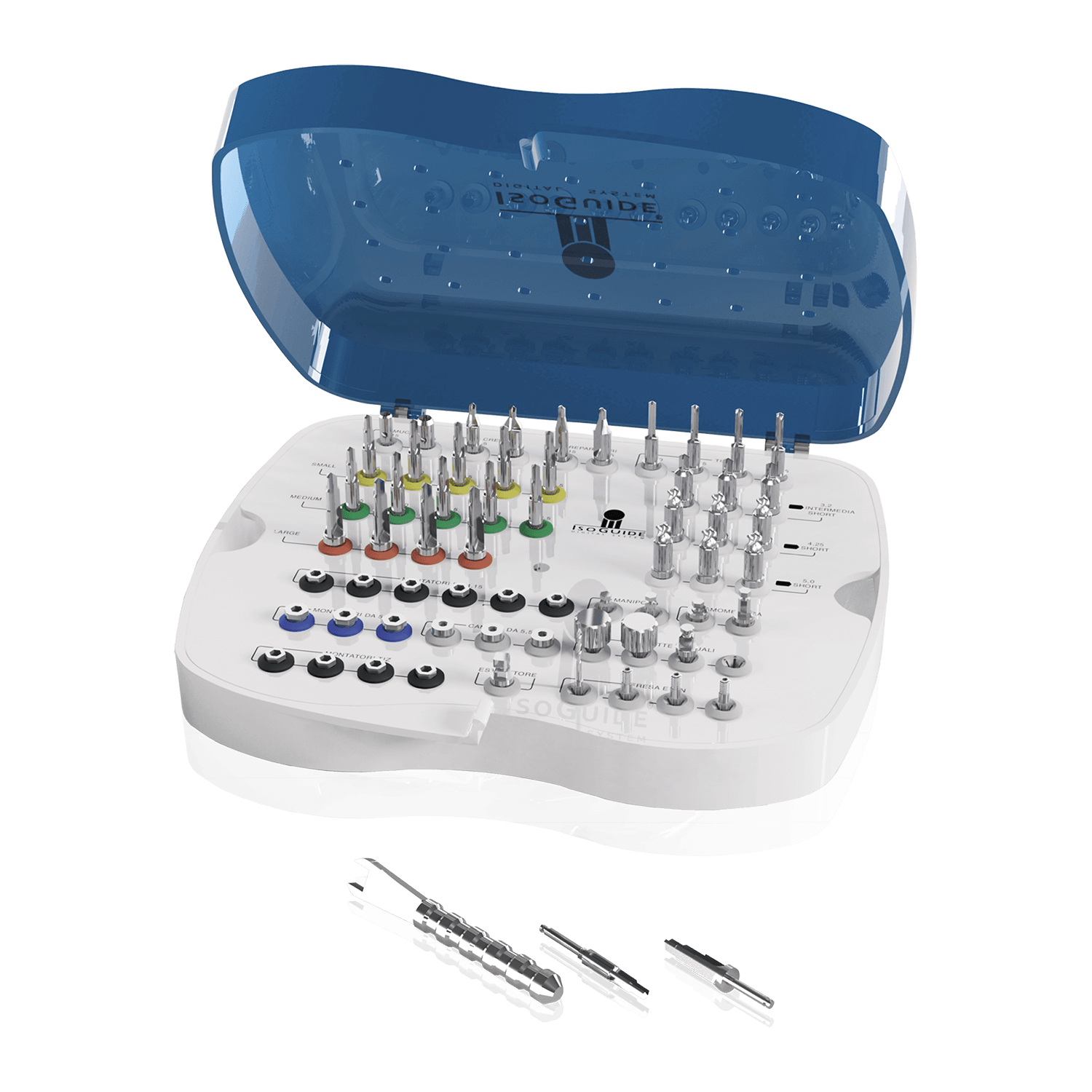

Digital surgical solutions: IsoGuide system

Subsidized financing plans

All Isomed products

Would you like to recive our catalog?

Fill out the form to receive the catalog in digital format of all our components and instruments.